We are proud to deliver Belmont Hub – a highly complex building project located in the heart of Belmont.

The Belmont Hub was established by the City of Belmont to deliver integrated cultural and community services to the local community comprising of a number of specialised spaces and facilities over 4 levels.

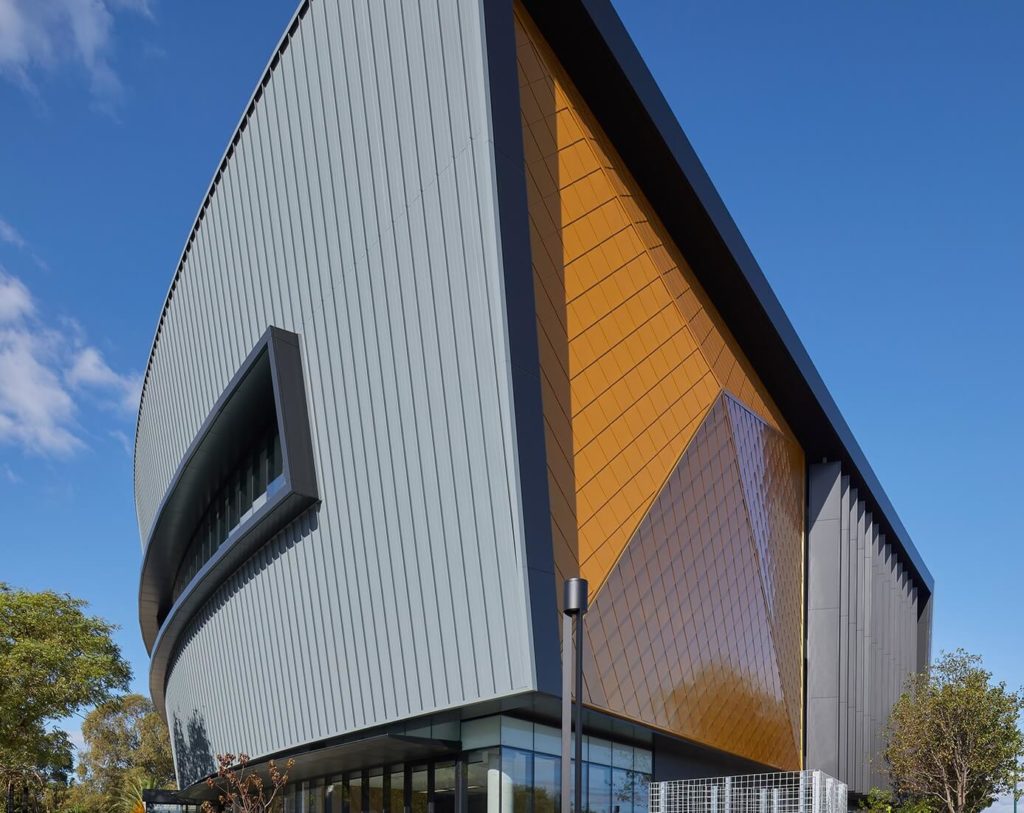

The Belmont Hub is an architecturally striking building that will become an iconic landmark feature in Belmont.

Our team worked relentlessly to deliver a facility that showcases distinctive complexity in geometrical design, uses multiple contrasting materials as well as utilising innovative construction techniques.

Some of the distinctive features of this project include:

STRUCTURE

FOUNDATIONS: The entire building sits on a 500mm thick insitu concrete raft slab with additional pad footings.

CONCRETE: The suspended floor slabs on each level were constructed using hollowcore planks and precast support beams. The beams and planks were arranged in grids to manage span lengths across each floor.

These were topped with two colours of 100mm thick polished concrete topping slabs in a hit and miss arrangement. The design of each concrete slab was highly segmented, contributing to approximately 27 pours per floor. Due to the large amount of small pours, each floor took approximately one month to complete.

POST TENSIONING ELEMENTS: The cantilevered southeastern end of the building required post tensioned cables to the slab ends on Levels 1 and 2.

STRUCTURAL STEEL: The architectural design of the building called for extensive curved and/or cambered steel. Every major piece of steel on the project was either curved or cambered, and specialised contractors were required to manufacture the bespoke structural steel work for the project. A total of 280t of structural steel was installed on the building.

EXTERNAL FINISHES

Several contrasting facade elements have been utilised on all sides to create a layered, textured building envelope.

Facade finishes include:

KINGSPAN SHINGLES

The Kingspan aluminium shingles on all sides of the building are a feature facade element of the facility.

These shingles feature on major panels on the northeast and southwest elevations. The shingles were installed on Kingspan’s proprietary BENCHMARK Karrier panels, removing the need for additional mounts for each shingle.

It was a time consuming process that involved meticulous attention to detail by our skilled tradespeople.

FEATURE SKYLIGHT

The central skylight is supported by a 20 tonne structural steel frame. The skylight sits over the central void that runs down the entire central spine of the building.

The lift is supported by an impressive 20-tonne steel frame and sits within an exposed space allowing visitors to see all the beams and mechanics of the equipment.

INTERNAL FINISHES

CEILINGS: In most spaces feature concrete bulkheads with timber slats and exposed ductwork. Autex acoustic panels in several different colours and cuts provide acoustic insulation while adding texture to the otherwise exposed ceiling elements.

FLOOR FINISHES: are varied throughout the building, with exposed aggregate polished concrete floors featuring prominently in the main areas of the building. Wet areas utilise vinyl flooring and carpet tiles have been used in office spaces.

WALL FINISHES: to Level 1 and 2 feature acoustic MDF panels prominently. Perforated timber veneer panelling clads feature walls in public areas. Windows on Levels 1 and 2 feature motorised blinds. Other wall finishes include: fibre cement sheeting, tiling, acoustic MDF panels, plasterboard (pain finish) and glazed partitions.

FIT OUT

Features of Ground Level include:

- End of Trip Facilities (Toilets, showers, lockers, bicycle storage)

- Library

- Senior Citizens Area

- Children’s Area

Features of Level 1 and Level 2 include:

- Museum area

- Administration Area

- Breakout areas, creche and office

PACT are extremely proud to see this complex construction project completed and in operation by the City of Belmont. It was an honour for our Team to work with the City of Belmont and we hope people enjoy this iconic building for many years to come.