Established by The City of Belmont to deliver integrated cultural and community services, Belmont Hub is a modern multi-purpose community building featuring a library over two levels, a digital hub, seniors’ hub and a state-of-the-art museum.

The technicality of the build, the complex construction techniques plus the type of materials used makes this project very unique to Western Australia.

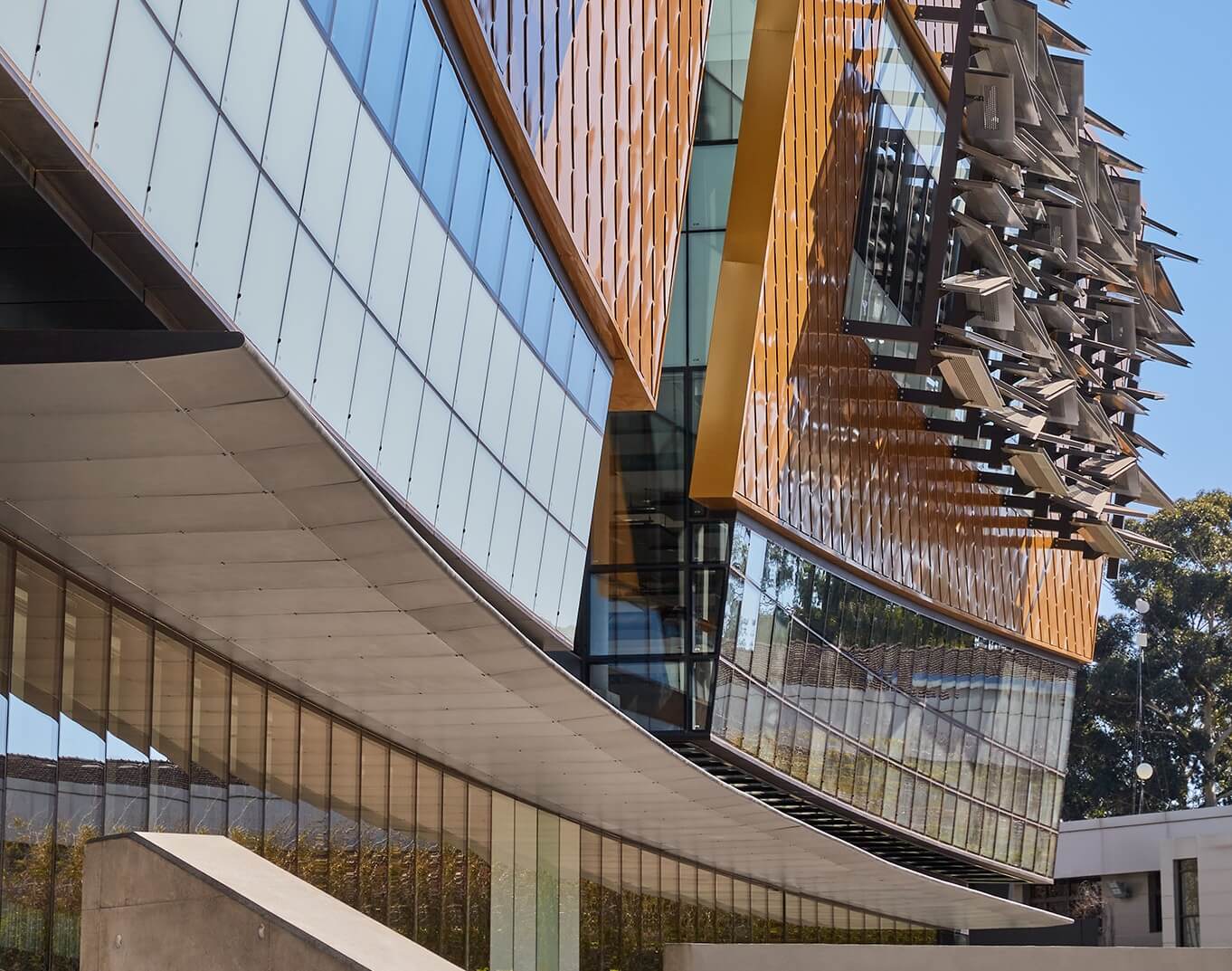

According to construction company PACT, who is a part of the ABN Group, the facade combines several different materials including curtain walling, Kingspan cladding, shingles and aluminium panels – all slanted at different angles around the building.

“The aluminium Kingspan shingles are a first for the WA construction industry,” said General Manager of PACT, Jason Thomson.

“These are imported from Europe and installed by a specialist. Depending on the angle, the different colours of the shingles give a three-dimensional illusion effect.”

Each 500mm x 500mm shingle had to be set out and fixed individually, making the installation of the 1,000 shingles a highly time-consuming process. On average, only 15 tiles could be fixed in any one day.

To create the large open spans, complex construction methods were required on each floor of the four-level building. A mix of in-situ beams, post-tension beams, pre-tension slabs and a polished concrete topping were utilised, meaning the normal 10-day process with most traditional suspended slabs, instead took 28-days on average.

PACT also dewatered, transferred and monitored four million litres of water per day during the basement excavation and construction works.

Ponds for discharge of the collected water were formed on-site using excavated material, and the mature trees within the protection zone were closely monitored to ensure they were not damaged.

Designed by award-winning architects, Bollig Design Group, Belmont Hub has many unique features. For example, the central glass lift is supported by an impressive 20-tonne steel frame and sits within an exposed space allowing visitors to see all the beams and mechanics of the equipment. The ductwork and electrical services also have a high level of exposure, giving the building a raw, industrial look.

The ceilings feature raw concrete structure, timber slats and Autex acoustic panels in multiple colours and cuts provide insulation and acoustic absorption while adding texture to the elements.

PACT Construction Manager of Belmont Hub, Steve Ball, detailed that the ambitious plan for the flooring required incredible attention to detail.

“The floor finishes are varied throughout – exposed aggregate polished concrete features prominently in the main areas of the building, the wet areas utilise vinyl flooring and carpet tiles are used in office spaces. By having the elements exposed, it left very little room for error,” he said.

Some of Belmont Hub’s most ambitious features include the floating staircase and central skylight. The veneer clad stairs have no supporting columns or beams underneath, and a striking skylight sits over the central void that runs down the entire central spine of the building.

The entire building sits on a thick in-situ concrete raft slab and every major piece of structural steel used was either curved or cambered.

Specialised contractors were required to manufacture the bespoke structural steel for the project, and bespoke designers and manufacturers were also required for the curved curtain wall of the façade.

PACT engaged a commissioning manager to oversee the services and achieve the centre’s Green Star requirements. Of particular focus was the complicated Building Management System which includes intelligent monitoring of energy and water consumption for the building. The project is targeting a 5 Star Green Star certification under the Green Star Design and As-Built tool.

Point Cloud Surveying was also used to ensure the high degree of precision required was achieved – numerous elements of the building, including the structural and facade elements, had to be carefully shop detailed to fit with the core building structure.

The use of the point cloud survey allowed shop detailing of the elements to be completed with accurate as-constructed information of the real building structure. Adjustments were made where necessary to ensure manufactured steel and facade elements would be successfully installed on site.

Working with a large number of high-quality architectural finishes and bespoke elements on Belmont Hub required PACT to implement some novel installation procedures on-site.

Belmont Hub, at 213 Wright Street, Belmont, is now open to the community.